airexpress® is a modular system of tubular profiles with flat or round sides, specially designed for compressed air conduction. It is anticorrosive due to its chemical composition, facilitating the conservation of the treated air; its smooth surface minimizes friction losses, its modular assembly of quick coupling simplifies its installation avoiding time losses and production costs.

The square pipes of the airexpress® line allow installation of hot service points and its versatile structure allows adaptability to design changes since it is a light, resistant system and its weight is equivalent to one third of the weight of a conventional pipe, in addition it is free of paint and maintenance.

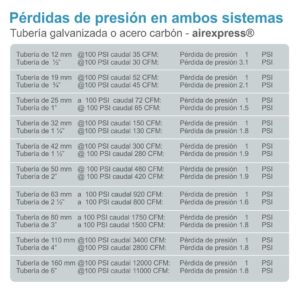

The pressure and volume of compressed air in the airexpress® pipe is constant, this allows optimizing the efficiency of pneumatic equipment. Airexpress® products contribute to energy savings by reducing pressure losses and leaks by up to 30% compared to a carbon steel pipe and it is a clean technology that protects the useful life of the different pneumatic equipment.

Advantages

– It is anti-corrosive due to its chemical composition, facilitating the conservation of the treated air.

– Its smooth surface minimizes friction losses.

– Modular quick coupling assembly that simplifies installation, avoiding loss of time and production costs.

– Square piping allows installation of hot service points.

– Versatile structure that allows adaptability to design changes.

– Light and resistant system, its weight is equivalent to one third of the weight of a conventional pipe.

– Paint and maintenance free.

– Constant pressure and volume of compressed air, which allows optimizing the efficiency of pneumatic equipment.

– Energy savings due to reduced pressure losses and leakage, up to 30% compared to a carbon steel pipe.

– Clean technology that protects the useful life of the different pneumatic equipment.

PHYSICAL AND MECHANICAL PROPERTIES

The data of these tests were taken under standard atmospheric conditions 20°C (293°K) and 1,013 bar (14.7 PSI).

Anodizing gives it greater resistance to corrosion and wear. The anodizing of airexpress® pipe is between 12 μ and 15 μ deep for domestic use; for export it will be between 15 μ and 17 μ which is the international standard.

The airexpress® pipe is resistant to corrosion attack by some chemical agents. For aggressive environments, which attack aluminum, a pipe with a special coating can be used.

Maximum working pressure 203 PSI (16 bar).

The tubing has been hydrostatically tested to 800 PSI (54 bar).

The airexpress® pipe complies with ICONTEC 5359 (Aluminum pipes for compressed air).

airexpress® tubing is ISO 9001:2000 certified.

airexpress® fittings are ISO 9001:2000 certified.

Complies with ICONTEC standard 3458 (Piping and installation marking). Complies with ISO 8573-1 (Air quality).

PHYSICAL PROPERTIES

MECHANICAL PROPERTIES

CHEMICAL COMPOSITION

FLOW RATES ALONG THE PIPE

Note: Flow rates are determined based on 1Psi pressure drop per 30 meters (100 feet of pipe).

Tested in accordance with ISO 2944, measured under standard atmospheric conditions, 1013mBar (14.7 PSIA and 20ºC 68ºF).

TECHNICAL SPECIFICATIONS

Dimensions, weight, pressure

Temperature

Roughness

AIREXPRESS® PIPE CATALOG

STANDARDS AND CERTIFICATIONS

Patented product

– INCONTEC NTC 5359 Certification; Aluminum Piping for Compressed Air.

– Raw material, complies with ISO 8573-1.

– Raw material, complies with ICONTEC 3458.

– The airexpress® pipe is ISO 9001:2000 certified.

– airexpress® fittings are ISO 9001:2000 certified.

– Complies with ICONTEC 3458 standard (Piping and installation marking).

– Complies with ISO 8573-1 (Air Quality).

Complies with the requirements of international standards:

ASTM B241.1 (Standard Specification for Aluminum and Aluminum Alloy Seamless Pipe and Seamless Extruded Pipe).

ASME B31 (Standard for Pressure Piping).

PIPE AND FITTINGS

Round Pipe, Square Pipe, Round Pipe Elbow, Square Pipe Elbow, Round Pipe Tee, Reduced Tee, Square Pipe Tee, Clamps, Straight Union, Female Threaded Union, Female Threaded Union (B), Male Threaded Union, Male Threaded Union (B), 6″ Flanges, Collars, Small outlet flange, Large outlet flange, Ceiling bracket, Wall or ceiling bracket, Wall bracket (L), Nipple nut, Ball valve (Male / Female), Wall connector, Reducing (Bushing / Nipple), Male plug, Plates, Hot piercing device, Vacuum clamps

ABOUT US

Ingeneumática S.A.S. Is a company dedicated to design, develop, produce and commercialize compressed air networks, as well as industrial automation; representing an integral solution in pneumatic systems through innovation for all types of industries, satisfying our customers with timely services and contributing in parallel to the development of all those who are part of it.

OUR NEW LOCATION

• Carrera 55B # 72A-94

Itagüí, Antioquia, Colombia

- (+57 604) 448 8836

- (+57) 314 890 9672 / (+57) 314 890 9668

- comunicaciones@ingeneumatica.com

- division.tuberia@ingeneumatica.com / (+57) 321 6409937

- division.maquinas@ingeneumatica.com / (+57) 314 890 9662

www.ingeneumatica.com